EJ2

Track Rat: B Series Axles

If

you road race or do HPDE with a Honda that has a B Series motor such

as a B18B1, B18C5, B16A2, etc, then you’ve likely run into axle

problems.

Figure

1: Integra Axle with Torn Outer CV Boot

Many

cars with continuous velocity (CV) axles, even street cars, encounter

torn boots every once in a while. But when you throw in hard braking

from 100 MPH to 60 MPH once every minute-and-a-half, or when you

subject your CV joints to excessive stress with a lowered car, or

when you toss R comps and excessive lateral loads at your vehicle,

you’ll quickly find the limits of physics.

Figure

2: Damien’s Dirt-Nasty Low “EK” Hatch Race Car

Excessive

heat from rotors, loads from cornering, and aggressive articulation

angles all result from the conditions mentioned above. With the

added heat and stress, the components inside of the CV joint

typically wear in an accelerated manner-- and for those who are

racing, that could mean a DNF or last place. Either way you’re

losing points toward your championship and wasting money with a

broken car on track.

This

writeup provides a solution for those of you who hate your axles. Do

you want to drive on R comps? Do you want to be dirt-nasty low? Do

you want to crack rotors with heavy braking? Well, you’ve come to

the right place.

Figure

3: The Chaos That is Racing

Problem

1: Grease

The first problem associated with many parts-store brand axles that

are made for B-Series-equipped Hondas is that they likely don’t

have enough grease in them. Even if they do have enough grease, one

has to question how high quality said grease is. When a single CV

axle costs $35, do you trust it to hold up to the stresses of racing

or track days?

Figure 4: These SurTrack Automotive Axles are Cheap at ~$35 from

RockAuto

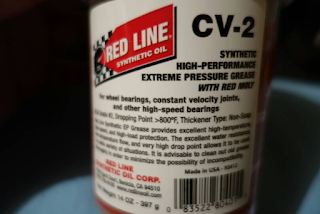

We solve this problem by replacing the old, crappy grease originally

present in your axles with high-quality grease. For this DIY, I

chose to use Redline CV-2.

Figure 5: Redline CV-2 “High Moly Content” Grease

Redline CV-2 is the grease of choice for rebuilding these troublesome

Honda B-Series axles as it is made by a reputable company, withstands

temperatures up to 500 degrees Fahrenheit, high pressures, which are

common in CV axles, and because it contains an “organic moly” as

stated by Redline. This organic moly is likely a compound referred

to as molybdenum disulfide. Due to its molecular structure, it

provides superior lubrication like graphite but it also adheres to

metal surfaces very well.

Figure 6: My Friend Alex Lubing up an Axle with Redline CV-2

Problem

2: The Heat

As

I mentioned at the beginning of this writeup, the axles are subject

to a lot of stress on a FWD race car. Heat is transferred from hot

rotors to the axle spindle through the hub and heat is generated by

the bearings in the CV joints as they rotate and articulate. The

effects of this heat can be exacerbated by other factors mentioned in

this article such as poor grease and poor manufacturing tolerances in

cheaply made axles.

If the grease can’t handle the heat, its lubricating properties

degrade, subjecting the bearings in the CV joints to excess

friction-- compounding the problem. If the ball bearings are pitted,

the bearing races are cracked, or the cages are cracked, the axle may

begin to vibrate and eventually fail catastrophically.

Figure 7: Cracked Cage on a Subaru CV Joint

To solve this problem, we firstly use better quality grease.

However, we can also vent the CV joints.

Venting

CV joints has not been empirically tested to the best of my

knowledge-- however,

it is a practice that has been employed in the Honda road racing

community for a long time by reputable axle manufacturers such as

Gator, RAxles, Insane Shafts, and Driveshaft Shop. While the

efficacy can be debated for days, it still doesn’t hurt to

understand the theory and

construction of axle vents.

Figure

8: Venting the Outer Boot of an Acura Integra Axle

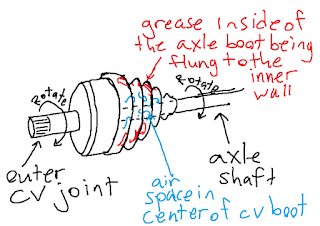

When the axle is rotating at a high speed, it is believed that the

centrifugal force generated by this behavior disperses any excess

grease around the inner diameter of the axle boot. This, in theory,

creates an air space in the center of the CV joint. Heat from the

hot, rotating CV joint is transferred to the air space, and if the

air is not vented, it is believed that this can accelerate axle wear.

Figure 9: Diagram Showing Air Pocket at Center of CV Boot

To evacuate this hot air, it is believed that a small “vent”

(which is actually a tube inserted between the boot and axle shaft)

can be used.

Figure 10: Diagram Showing Added “Small Tube” Which Serves as a

Vent

Problem

3: Manufacturing

I’ve taken apart brand new parts store axles that have failed on my

race car and discovered that they were adequately greased, but failed

anyway. This, and other anecdotal evidence I’ve read online and

heard about from other B Series drivers leads me to believe that

“they just don’t make ‘em like they used to.”

This last section isn’t me saying that a parts store axle with high

quality grease can’t last. Contrarily, I have seen and heard of

people regreasing parts store axles with high quality grease and

having great success at a reduced cost. However there is a generally

true inverse relationship between quality and cost with auto parts

that suggests machining tolerances and material quality may be

compromised for the sake of pricing-- especially with economy-priced

axles.

So, let’s not focus on how true the above statements are. Let’s

just make sure that our axles are well made. The easiest way to do

this is with visual inspection and with precision measurement tools.

Figure 11: A Starrett 0-1” Micrometer I Bought for $10 on OfferUp

When

disassembling your axles to regrease and vent, measure any components

you can and visually inspect the friction surfaces. Visual

inspection should always be implemented as it is cheap and easy if

you know what to look for. If you don’t have precision measurement

tools, it’s not the end of the world, but they do help.

Starting

with the outer joint of an

Acura Integra CV axle, it

consists of six ball

bearings, an inner race, a cage, and

an outer race which is integrated into the spindle.

This type of CV joint is

called a “Birfield joint.”

Figure

12: Diagram of Outer CV Joint

Disassemble

the outer joint and begin visually inspecting the components. The

following video is a great DIY on how to disassemble the outboard

joint of a CV axle: https://www.youtube.com/watch?v=3-R11jtnyV8.

Things to look for during

inspection include: metal

pitting, hairline fractures and cracks, and discoloration.

Figure

13: Discoloration on the Spindle Caused by Overheating

If

you can see pitting on the metal surfaces, it could be due to

contaminants in the grease such as sand that entered through a torn

boot or corrosion from moisture. If you see discoloration, it is

likely that grease was not lubricating effectively

in the affected

area and the metal is now distorted. If you see cracking, the

affected area may have overheated at some point or may have been

constructed from cheap metal.

Figure

14: Ball Bearings with Spalling

A

well-manufactured CV axle, such as an OEM unit, will show minimal

signs of wear on the friction surfaces. I

have disassembled OEM Acura Integra Axles with over 150,000 miles on

them and torn boots with nearly perfect looking wear surfaces.

Figure 15: Outer Races of Said 150,000 Mile Axle with Minimal Wear

Once you’re finished your visual inspection, measure whatever you

can with precision measurement tools. Engine builders use this

process when disassembling motors. Critical dimensions are measured

to the nearest one-thousandth, sometimes the nearest ten or

one-hundred-thousandth of an inch to gauge the health of various

components. If the components are found out of spec, they are sent

to a machine shop where they can be brought back into spec with

specialized machinery.

Figure 16: Using an Outer Diameter Micrometer to Measure Ball Bearing

Diameter

For the outboard joint of a CV axle, one easy component to

“blueprint” is a ball bearing. Take several diameter

measurements of the ball bearings and compare the results against all

bearings in the axle set. Mark each ball bearing with dots so that

outliers can be identified. Record your results for future rebuilds.

My OEM axles that I rebuilt all had healthy looking ball bearings

with outer diameters that were the same to one-thousandth of an inch.

Figure 17: Recording Ball Bearing Diameter Results

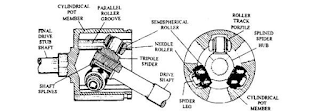

The process is the same for the inboard CV Joint. Disassemble,

clean, visually inspect, and blueprint what you can. The inboard CV

joint used on B Series Hondas and Acuras is known as a “Tripod

joint.” The picture below shows a cutaway view of the side of the

inboard joint on the left, and on the right, a cutaway view of the

front.

Figure 18: Tripod Type CV Joint (Image from:

http://what-when-how.com/automobile/universal-joints-automobile/)

Below you’ll see the inboard spindle that houses the majority of

components comprising the inboard joint assembly. Again, this is an

OEM unit and looks nearly immaculate after years of abuse.

Figure 19: OEM Honda Tripod Joint Housing (“Cylindrical Pot

Chamber”)

When I disassembled the inboard joints, I only blueprinted the outer

diameter of the “semispherical rollers” as outlined in Figure 18.

But I could have also disassembled these “rollers” and

blueprinted their internals as well.

Figure 20: Semispherical Rollers Cleaned and Recently Inspected

Again, when blueprinting the inboard side, the more measurements you

can take the better-- but remember, all of the measurements are

relative (unless you’re an engineer at Honda and have access to the

dimensions you need!) Regardless of what the measurements are,

record them and keep them for future axle rebuilds. More data is

always better.

The

Finished Product

Disassembling,

cleaning, inspecting, greasing, venting, and rebuilding your old

axles can be a hassle, but if you’re looking to save a buck, the

tips in this writeup should help. When you buy a project car, save

the OEM axles! When your friend wants to throw out their OEM axles,

save the OEM axles! And if you’re at a junkyard and you see OEM

axles, save the OEM axles!

#SaveTheOEMAxles

Figure

21: An Assembled, Regreased, Vented, and Blueprinted OEM Honda Axle

Thanks

for reading all. Your time is greatly appreciated.

Figure

22: Chelsea the Civic

Helpful

Links

CV

Joint Types:

http://what-when-how.com/automobile/universal-joints-automobile/

How

to Disassemble a Birfield Joint:

https://www.youtube.com/watch?v=3-R11jtnyV8

How

to Replace CV Boot:

https://www.youtube.com/watch?v=-S-ofMoWsr0&t=329s

Band

Tool Operation: https://www.youtube.com/watch?v=mBsqyH6xhw0

How Does Moly Grease Work: http://www.nitronine.com/how-does-moly-grease-work/