Last season, I was in a rush to get my car together. I skimmed over a lot of details while doing so in an effort to pass competition school with the National Auto Sport Association (NASA) and to race with my friends in the Honda Challenge H4 Series which we were reviving in the Northeast.

In the process, I ordered a DC Sports header with a 2.25" collector for an exhaust system that had a diameter of 2.5". I was struggling to make it to my first event of the season at Lime Rock Park to test the car. And on my final weekend before trailering up to Connecticut, I was faced with the dilemma of making this header work with my exhaust system.

With no flux wire or gas, and minimal welding experience, I welded the monstrosity you'll see above. This monstrosity is a 2.5" PLM (Private Label Manufacturing) test pipe. I thought I had a 2.5" collector on my header, but this is when I first discovered that I was mistaken. As a result, the collector on my test pipe did not fit and I was forced to improvise. So, I cut the flange off of my 25-year-old catalytic converter, cut the flange off of my brand new, shiny test pipe, and welded it onto the test pipe.

As you may be able to see, this last-minute concoction left a leading edge entering into the test pipe, providing for turbulence and most likely a loss of power. On the dyno at Lime Rock Park after a race, my car had less horsepower than the three other H4 cars dyno'd-- most likely due to this and my janky intake, which I will not discuss in this post. Additionally the welds were not very good as you can see below...however, the test pipe held up for a full season of racing.

When the off-season came, I knew I had to put this on my list of improvements for the 2019 racing season. So, I started by purchasing a $211 PLM header off eBay.

If you'd like to see more photos like this, you can follow me on Instagram:

This header is a replica of an SMSP Tri-Y Header. It has a 2.5" collector and is a 4-2-1 which leads to less turbulence and higher flow than the 4-1 DC-Sports header I was previously using. It's also fully stainless steel, very light, and tig-welded together.

The reason I was able to get this header for so cheap is because it is an open-box sale. PLM and 1320 Performance are two brands which both sell a lot of headers for Honda. And they have sales like this going on a lot of the time.

Think of it.

Your Facebook friend car meet fanatic wants to make 5 extra horsepower on the butt dyno. He or she goes on eBay and buys a brand new, shiny, tig-welded header that has no damage at all and intends to put it in a car that is likely daily driven, and if not, is street-driven in his or her leisure.

This header is shipped through FedEx, UPS, USPS, or another service that throws the box around, sets it on fire, or dips it in a bath of acid (they damage it). It gets to the customer, and they no longer want it.

As a racer, you can take advantage of this scenario by buying the scratched or minorly dented header second-hand, and you have a new, but unboxed item delivered to your door for a fraction of the cost.

Next, I purchased a new PLM test pipe. This extendable test pipe was ~40-50 dollars and its length can be adjusted to fit your new header to your existing exhaust.

I mounted the header, mocked up the test pipe and got to work cutting and welding. Having a vise is great for almost anything in the garage. I even use it to hold pipes or other objects that need welding as I don't have a welding table, I have a wooden table. The picture below shows one section of my three-piece test pipe in a vise with a white mark around it where it is to be cut.

After cutting, I then mocked the test pipe up between the header and the exhaust one more time and welded the pipe in the appropriate spot. This time I used flux core wire, to preclude accelerated rusting as seen on my older test pipe. A better weld with less slag and less porosity would likely be achieved with gas, but this blog is about doing racing on a budget, so forget about it.

Mounted up, this is what the test pipe looked like. It fits well, not pulling the exhaust too far forward or pushing it too back.

I also noticed that the SMSP tri-y header was touching the oil pan after I installed it. Even in a 25-40 minute race, conductive heat transfer from a header to an oil pan could be bad. You see, exhaust gases leaving an internal combustion engine's cylinder are typically around 1,000 degrees F (based on passing knowledge). I knew I had to increase the clearance between the header and the oil pan.

Oil pans are cheap and made of soft, malleable, durable steel. Headers are expensive and made of more expensive stainless steel. When push comes to shove, one must give-- and in this scenario, I made the pan give with a hammer-- I mean I massaged it gently and carefully as I am a skilled fabricator:

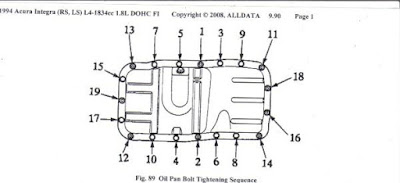

In the above picture, the horizontal lines at the bottom of the pan mark where the header and oil pan were originally touching. The dots at the top of the oil pan tell me in which order I need to torque the oil pan bolts. 5 bolts tells me that a given bolt is the fifth bolt in the sequence, 17 dots tells me it's the seventeenth bolt. There are over 17 bolts on a B Series oil pan.

The hardest work was complete, but the last thing to do was to install the O2 sensor. The problem with this is that on a 1992-1995 Honda Civic with a B Series Engine from an Integra or something similar is that the O2 sensor wire for the B Series Engine is too short for the Honda Civic engine wiring harness. As a result, you have to lengthen it. I began by cutting my brand new Denso sensor in half.

Next, I grabbed some wire, measured from the sensor to the connector in the engine bay, and cut the appropriate amount to connect the O2 sensor on the Integra engine to the Honda Civic harness.

Here's a tip: when you take apart any electronics for anything, save the wires. Good wire is hard to come by at local hardware stores and if you can find it, you have to pay for it. I save wire from cars that I part out, or machines that break around the house. I then take these wires and use them in automotive projects. I haven't spent money on wire in three years.

Then I grabbed my soldering gun and got to work. I cut all wires needing connection, stripped all said wires of their insulation, soldered all wires together, and added heat shrink around the soldered connections to prevent damage via water intrusion or other external factors.

Here is the heat shrink I applied. You can get it from a local hardware store, a local auto parts store, or online:

Lastly, I taped the wires together and wrapped the lower part of the wires that sit next to the header with insulation. I was careful to wrap the soldered joints with tape so that they would not flex. I was also careful to ensure an equal spacing of tape about the length of this loom of wire.

The finished product is shown below:

Lastly, I installed the O2 sensor...

...And I fired up the car. The car was difficult to start at first, but ended up idling and running with no check engine light at temperature for several minutes. The car was sitting for months not having turned over and it didn't even need a jump start. I love this Honda.

I have some actions going forward to make the car faster, but for now I am focusing on getting it on track next month (April of 2019) at Lime Rock Park for testing with NASA NE.

I appreciate you all reading and wish you the best. Peace!